Design & Engineering

Design & Engineering Solutions Built Around Your Success

Exceptional manufacturing begins long before production. At BERMO, design and engineering are integrated into every stage of the process to ensure parts are manufacturable, cost-effective, and repeatable. Our engineering-first approach focuses on collaboration, accuracy, and delivering the best possible results for your program.

A Customer-First Engineering Approach

Most suppliers build the print. BERMO builds a partnership.

From your initial quote through production launch, we evaluate your 3D model for manufacturability, cost drivers, material efficiency, weld and forming strategy, automation opportunities, and anything that could impact quality or lead time.

Instead of keeping recommendations internal, our engineers communicate directly with your team to discuss design intent, potential improvements, and the best path forward. This open exchange eliminates surprises and ensures alignment from the start.

A Structured Engineering & Activation Workflow

Our engineering process is designed to reduce risk, improve cost, and ensure a smooth production launch.

Solid Model Intake

Every project begins with a detailed analysis of your CAD model to identify opportunities and flag potential challenges early.

Cross-Functional Review

Engineering, Quality, and Production collaborate to define the ideal stamping, forming, and welding approach; review tolerance and datum schemes; and determine fixture, tooling, and automation needs.

Customer Collaboration

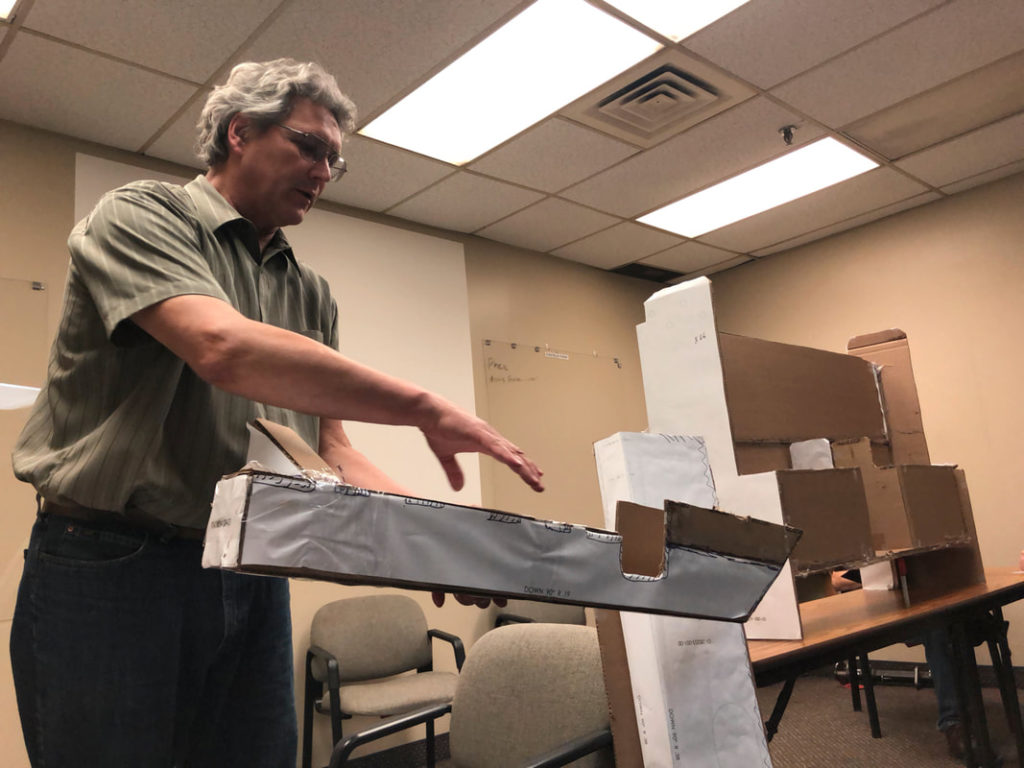

Insights and recommendations are shared directly with your engineering team—virtually or onsite—to ensure clarity and alignment on manufacturability and performance targets.

Finalized Build Plan

Once the approach is confirmed, we create SolidWorks-based tooling models, process sequences, routing, and cost structures, and prepare all required documentation for PPAP, FAI, or customer-specific standards.

This disciplined, front-loaded process minimizes risk, reduces rework, and shortens time to production.

Engineering Expertise That Adds Real Value

With deep experience in metal stamping, forming, welding, and fabrication, our engineers understand how design choices affect manufacturing. We evaluate your part holistically to improve manufacturability and long-term performance.

This may include optimizing weld strategy, converting manual welds to robotic operations, simplifying assemblies, improving material utilization, tightening functional tolerances, or enhancing repeatability. These improvements don’t just reduce cost, they elevate the reliability and quality of the final product.

Support From Quote Through Launch

Our team stays involved from the moment a quote is submitted through every design iteration and into final approval. Customers value our hands-on approach because we provide proactive recommendations, not reactive corrections. We bring ideas, solutions, and engineering insight at every stage.

BERMO Delivers Engineering and Design Solutions

Whether you’re launching a new part or optimizing an existing one, BERMO’s engineering team is ready to improve manufacturability, reduce cost, and enhance long-term performance.

Request a quote and see how an engineering-first approach can strengthen your next project.

BERMO is a trusted U.S. precision metal manufacturer specializing in stamping, laser cutting, forming, welding, assembly, and full-service fabrication for OEMs in agriculture, transportation, medical devices, fitness, automotive, and electronics. With more than 65 years of experience and advanced capabilities, including in-house tooling, progressive stamping up to 600 tons, 12kW fiber laser cutting, CNC press brake forming, and automated welding systems,

BERMO delivers high-quality, repeatable parts and turnkey assemblies. Our integrated processes, modern equipment, and customer-first approach ensure reliable performance, cost-effective production, and fast turnaround for both short-run and high-volume programs.